Case Study

Delivering On Schedule

Issue:

Boeing was worried they would slip delivery of their first 747-8 freighter. The aircraft was no longer in the factory, and changes from certification had to be made in the field. Late delivery would result in harm to their brand and a hefty financial penalty.

Actions:

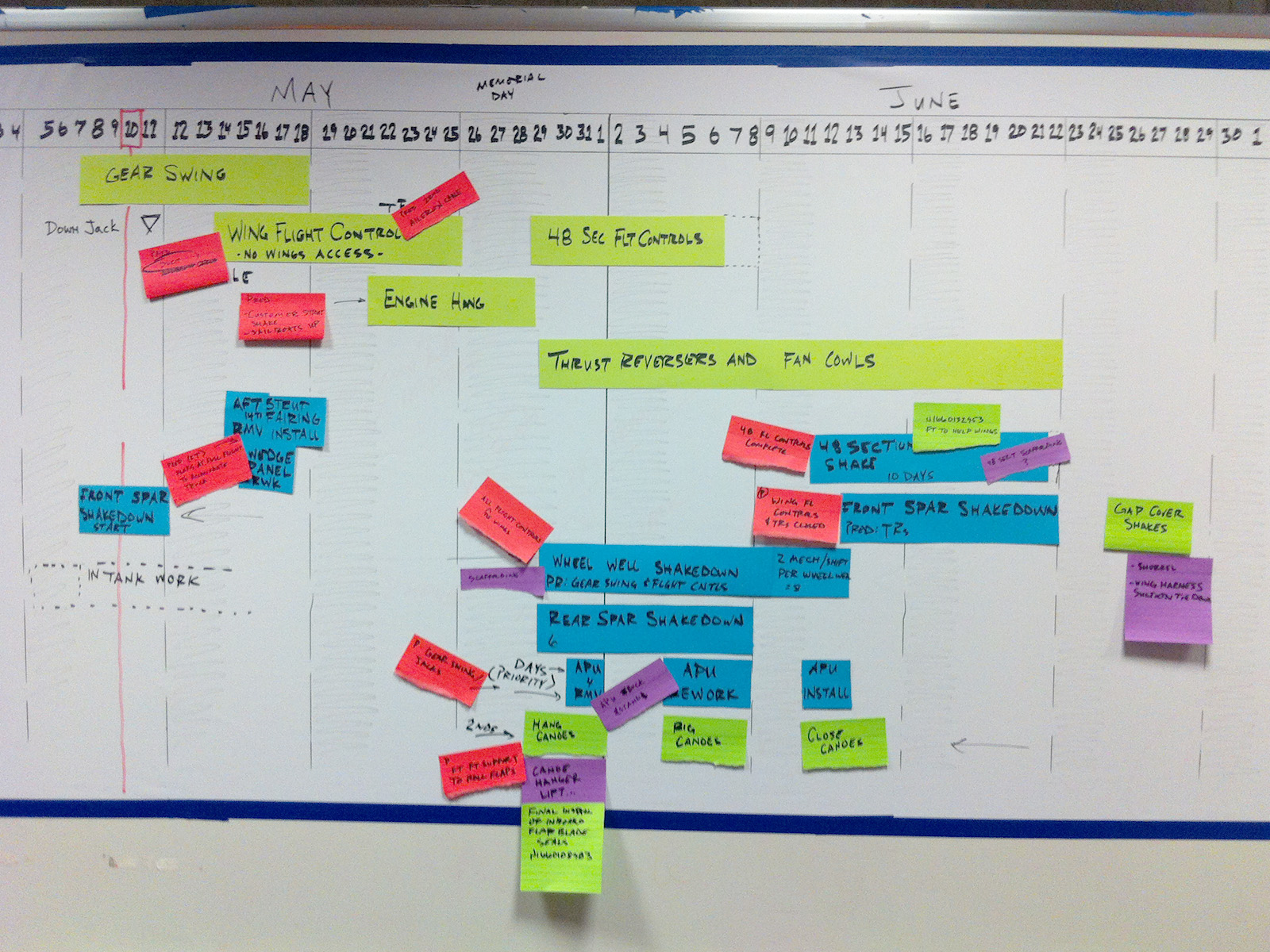

The Manager determined that Interiors and Wings were most at risk of missing their schedules. Interiors because of the sheer volume of work, and Wings because they had to complete a high volume of work concurrent with Electrical, Engines and Functional Test in the same workspace.

We optimized the plan for interiors, and coordinated it with Stores, enabling them to kit and stage parts ahead of the build. We planned the sequence of work for Wings and layered in Electrical, Functional Test and Engines. We then optimized the schedule and coordinated progress daily against the plan.

Results:

The team reduced manpower and completed and delivered the aircraft on schedule. The customer was delighted and sent lots of pictures of the aircraft being loaded and delivering its first payload.